Power Washing at Heights

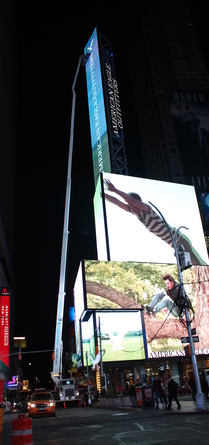

How Alpha Platforms Gave Times Square's 250-foot-tall LED Light Tower its First Power Wash in a Single Night

What was the challenge?

The American Eagle Outfitters flagship store in Times Square was built in 2009. It stands out among the bright lights of Times Square with its 250-foot signage tower wrapped in over 15,000 square feet of LED lights. For nearly 20 years, the LED-studded tower served as American Eagle's HD digital canvas to blast branded content 18 hours a day. Besides rain and melting snow, however, the top of the tower has never been washed.

The local lighting board that maintains Times Square's lights and fixtures reached out to Alpha Platforms for assistance in power washing the American Eagle's LED light tower. The client had at their disposal an old 130-foot bucket truck that would not reach the tower's top portion. So, the client planned to hire Alpha Platforms to wash the top of the tower on the first night and wash the lower part of the tower on the second using its own equipment.

The challenge was to access all 15,000 square feet of lights topped at 250 feet while providing a safe and stable environment to thoroughly power wash this critical American Eagle brand asset. The washing had to be done with minimal interruption to one of the nation's busiest transportation and pedestrian traffic hubs – The Times Square.

What was the solution?

What was the outcome?

It was a pleasant surprise for the client that they didn't need a second day to wash the lower part of the tower with their 130-foot lift. The Alpha operator's expertise, the 250-foot boom's reach and lift, and Alpha's experienced traffic team were the efficiencies that enabled the power washing of the entire tower in just one night.

- 12-foot extra large cage

- 1,322 lbs lifting capacity for crew, equipment, and materials

- Cage rotation 2 x 200°

- Side reach up to 130 feet

- Unique "under and up" or "up and over and back" access

- Smooth controlled motions to move close to and around glass and fragile structures

- Jib length 49’2’’

- Parking in tight spaces 8’3’’ wide

Alpha Platforms has helped hundreds of teams like yours

Customer Testimonials

from Case Studies

Great experience! First time on the 300 foot boom for a Local Law Facade Inspection. Vadim, the operator, was in complete control of the equipment and made the whole process smooth. Flagmen secured the area below and allowed my Client to operate their hotel without any disturbance. Honorio Designs Architecture, PLLC

Excellent service, arriving on time every day, responsible with the load limit, very attentive to the lubrication and controls of the crane.

Excellent team working with us, always willing to do anything for the best

It was a pleasure to work with Alpha Platforms, the crew was skilled and helpful, the equipment was top-notch. Our installers appreciated the security of the platform vs working off of a swing stage, it made their job easier and more efficient. From the first meeting thru to the end of the work day everything ran as smoothly as it could. We will definitely be partnering with Alpha Platforms on future projects. Thank you for your help!

I had an emergency project on a 140' high voltage tower and needed Alpha Platforms next day. They were so helpful and expedient walking me through the entire process so I was comfortable with the deal. They showed up to my site next day and cut about 2 days off of the project due to the safety, speed and efficiency of their lift and operators. I'll never rent or hire another lift company. I would recommend Alpha platforms for all your high reach needs.

Jon told me that it was a pleasure to work with Alpha Platforms, the crew was skilled and helpful, the equipment was top notch. Our installers appreciated the security of the platform vs working off of a swing stage, it made their job easier and more efficient. From first meeting thru to the end of the work day everything ran as smoothly as it could. City Sign Service, Inc. will definitely be partnering with Alpha Platforms on future projects.

That is a fine piece of equipment! And the competent, professional group that goes along with it is just the cherry on top. I really appreciate everything. I'm sure we'll be able to use Alpha again in the future as we get these opportunities. In fact, it will only help our business knowing we have a safe, reliable solution to these over 50‘ height challenges.

We had an exceptional experience with Alpha! They are professionals, great operator team. Overall reliable, recommended will certainly return for my future needs hands down.

My company used alpha lifts to clean a 14 floor building and they were great. Very accommodating, always on time, and will work with you to get the job done safe and sound. The lifts they provide are state of the art and can pretty much reach any low rise building under 250 feet. I’d recommend them to anyone doing window cleaning or facade cleaning, or anything king of height access work!

We wanted to give it a try and see what this boom truck could do. We loved the idea of a wide basket that could reach up to 30 feet and get to the brick wall over the roof. The main reason we loved the truck was how it maneuvered the boom to lower the bricks inside a dumpster, which was located behind the truck. It saved us at least one extra day of work. It all went great.

Alpha has the most efficient and leanest site setup time I’ve ever seen. My brother, who is the top climber of our group, first struggled to understand how this cage could go around the tower better than the crane - and when it did the whole 360°, he became a believer. Also, each laborer said how incredibly safe they felt - very different from the small crane basket. We were able to secure and push back the panels in place without the basket ever moving.

The project was performed successfully, and we were really glad to have contactless means of reaching the building, as we all know that pipe scaffold might damage the structure, in this case, very very sensitive.

access project you

need help with?

We received

your request

as soon as possible